Analysis

Medical Devices

Case Study: Using FEA to Accelerate Catheter Development

Background

A new catheter sheath was being developed using hypotube with precision micro-cuts to achieve specific flexibility and

torsional stiffness characteristics. Several cutting patterns were under consideration. The development team followed

the traditional design–build–test cycle, which involved long vendor lead times and extensive bench testing.

Traditional Development Approach

Process: Design patterns in CAD → Manufacture prototypes → Perform physical tests → Iterate based on results.

Cycle Time: ~4 months per iteration.

Limitations: Slow feedback loop, high cost of prototype production, limited ability to explore multiple designs.

Proposed Alternative: Finite Element Analysis (FEA)

Approach: Use FEA to simulate catheter flex and torsion behavior directly from CAD models.

Effort Required: ~10 hours to prepare and run simulations.

Advantages: Rapid design iteration, early elimination of poor designs, reduced costs, more data-driven

decision-making.

Actual Outcome

The team continued using the traditional approach. The first iterations took over 4 months, and critical flex/torsion data

was only available after full prototype testing. Several cutting patterns were built and tested that could have been

screened out virtually.

Missed Opportunity

• Time savings: Virtual evaluation could have provided insights in days rather than months.

• Cost savings: Fewer prototypes and test cycles.

• Risk reduction: Early design guidance before committing to expensive builds.

Lessons Learned

FEA is not a replacement for physical validation—but it is a powerful front-end design filter. Early adoption of simulation

tools can accelerate development, cut costs, and focus testing on the most promising concepts.

Also, combining FEA with Design of Experiments can lead to even greater savings. These tools work throughout the entire product life cycle.

A blog article here goes into much more detail.

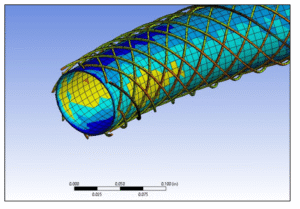

In another design/analysis effort, a more complicated catheter assembly was modeled in Solidworks and converted to an FEA mechanical analysis model. This particular design’s intent is to provide high flexibility for a high-tortuosity environment without buckling. Stay tuned for detailed analysis results!

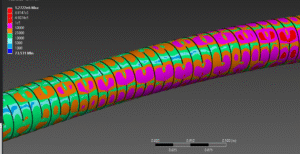

Laser Cut SS hypo tube showing mesh detail

laser cut hypo tube stress – psi

Distal access catheter bending stress