Why the R-3350 Engine Caught Fire: A Critical Design Lesson in Aircraft Engineering

Introduction

In 1937, the Curtis-Wright R-3350 radial engine ran its first test. At the time, it was the largest double-row, air-cooled radial ever built, and later versions produced over 3,000 horsepower. The U.S. military used the R-3350 during World War II, powering legendary aircraft such as the B-29 Super Fortress and the early Lockheed Constellation.

But despite its size and power, the R-3350 had one major flaw — it had a dangerous tendency to catch fire. This design issue led to tragic accidents, high maintenance costs, and one of the most infamous reliability problems in aviation history.

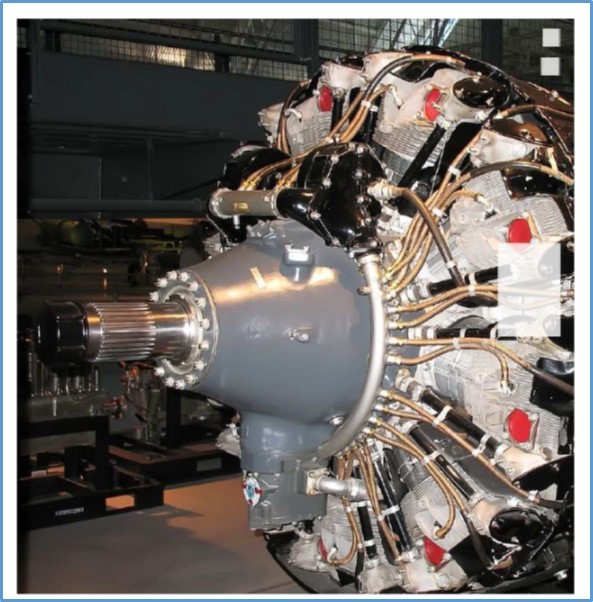

Figure 1 – static display of early R-3350 with exhaust ports (red) facing forward.

The Forward-Facing Exhaust Problem

One of the biggest design flaws was the forward-facing exhaust stacks on the front row of cylinders.

-

On the earlier R-2600 engine, the exhaust ports faced rearward, sending heat away from the engine.

-

On the early R-3350, the exhaust ports faced forward, directing 2,600°F gases back toward both rows of cylinders.

-

This poor thermal design destroyed exhaust valves and contributed to engine fires.

Why this design? Likely to cut manufacturing costs — forward-facing stacks were shorter and easier to form, connecting straight into the front collector ring. Unfortunately, this shortcut came at the expense of reliability.

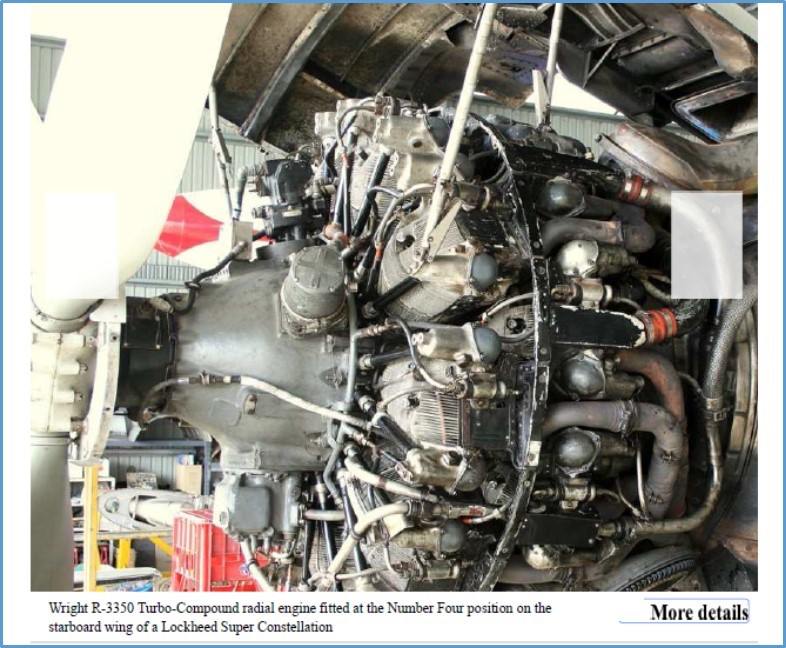

Figure 2-Lockheed Constellation R-3350 engine installation showing rear-facing exhaust manifold for front cylinders.

Deadly Consequences

The flaw wasn’t just theoretical. It caused real-world disasters:

-

Exhaust valve failures that led to in-flight fires.

-

B-29 crashes, including on one of the prototype test flights.

-

Magnesium alloy components made fires worse, burning hot and uncontrollably.

During early bombing raids over Japan, the B-29’s engine reliability was so poor that General Curtis LeMay had engines swapped after just 25 flight hours — barely two missions.

Postwar Fixes and Improvements

After World War II, engineers made crucial changes:

-

The Lockheed Constellation featured rear-facing exhaust manifolds.

-

The surviving airworthy B-29, Fifi, was later upgraded with postwar engines. It was a 9-year effort to make the conversion to better engines.

Additionally, Pratt & Whitney’s rival R-2800 engine, which used forged cylinder heads instead of weaker cast heads, proved far more durable. And did not have forward-facing exhausts.

How Modern Engineering Could Have Prevented It

If engineers in the 1930s and 1940s had today’s tools, the R-3350’s flaws could have been caught before mass production.

Step 1 – Linear FEA Thermal Analysis

-

Use conduction, convection, and radiation heat transfer models.

-

Identify hot spots and estimate valve/cylinder head loading.

-

Cheap, fast, and ideal for early triage.

Step 2 – CFD Simulation

-

Apply high-fidelity CFD (ANSYS CFX, Fluent, or similar) to model exhaust flow.

-

Validate with existing R-2600 test data.

-

Adjust input variables to replicate real conditions.

Step 3 – Hardware Testing

-

Rebuild an R-2600 with forward-facing exhaust stacks.

-

Compare measured cylinder and exhaust temperatures with simulations.

-

Confirm if failure modes match predictions.

Engineering Lessons from the R-3350

The R-3350’s history gives us key takeaways:

-

Don’t trade reliability for manufacturing simplicity. Straight exhaust stacks saved money but cost lives.

-

Material choice matters. Magnesium alloy parts worsened fires; forged cylinder heads outperformed cast ones.

-

Simulate early, test smart. Use CFD and FEA before committing to tooling and production.

-

Design for maintainability. Wartime maintenance practices proved unsustainable.

Conclusion

The Curtis-Wright R-3350 was a powerhouse that pushed engineering boundaries, but its forward-facing exhaust flaw nearly doomed the B-29 program. Modern tools like thermal FEA and CFD simulation show how these mistakes could be avoided today.

For engineers, the lesson is clear: analyze critically, simulate early, and design beyond the production line. History proves that even small design shortcuts can lead to catastrophic results.

Norman T. Neher, P.E.

Analytical Engineering Services, Inc.

Elko New Market, MN

www.aesmn.org