Performing a stress analysis only might not be sufficient to assess the durability of a product. When a product experiences complex load conditions including time variations, the simple stress analysis can lead to incorrect critical locations and/or an overdesigned part. An in-depth fatigue analysis must then be carried out to correctly estimate the life of a product.

Running a fatigue analysis is a growing trend in mechanical parts and assemblies. You must already familiar with stress analysis, as it is the basis for fatigue analysis. Stress or strain information from a stress analysis is the basis for predicting how many lifecycles a component will last. While this can be done by hand, using FEA or hybrid methods produce the lowest cost, and most accurate results.

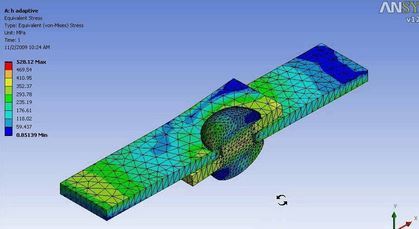

Secondly, fatigue isn’t something that happens only at the point of highest stress in the material. It happens everywhere. If the load changes as the component moves through the load cycle, there may be multiple peak stress areas. Furthermore, the failure may happen in an area with somewhat high stresses in every load event, but never the peak stress. This means that accounting for stress at every point in the model is necessary. Manual calculation methods are complex, time-consuming and error-prone, which is why FEA is an excellent tool for fatigue analysis.

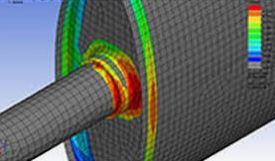

We use FEA along with engineering calculations in order to understand the rate at which products and structures fatigue and how to best implement design improvements to economically improve their durability. Using FEA we can locate stresses where cracks are likely to initiate. The same FEA results can then be used to determine how many load cycles it will take for the crack to propagate to failure. All of this durability and safety information is provided while your design is still just on the computer. You will have every opportunity to make adjustments and have the analysis verify the durability improvement.